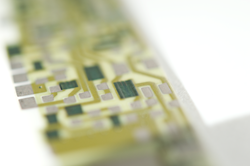

Thick Film Hybrid Circuit Boards

Corintech has been a leading specialist in the design and manufacture of thick film circuit board microelectronic assemblies since 1977.

What Are Thick Film Circuit Boards?

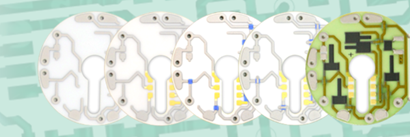

Thick film hybrid circuits are made using a print & fire (P+F) technique. This involves a combination of multi-layer screen printing of precious and semi-precious metals (Au, Ag, Pd), as well as the firing of tracks and precision resistors onto a range of ceramic and metal substrates. Surface mount components and bare die components with wire bonding can also be incorporated, and optional full encapsulation provides greater environmental protection. The use of different pastes allows the production of conductive tracks as well as resistors, which can be custom specified and then laser-trimmed to a high level of accuracy, offering an exact choice of value so that no compromise in design is necessary.

What Are Thick Film Hybrids Used For?

Thick Film Hybrids are ideal for environments where a high level of reliability is needed as they can withstand a much wider temperature range and have higher durability than conventional PCB assemblies.

Thick Film technology is used extensively in aerospace, defence and automotive applications. However, its durable and reliable nature is starting to appeal to a broader market. As an experienced company in this technology, we are the perfect partner to develop and manufacture thick film circuit boards to suit any application.

What Are The Benefits Of Thick Film Hybrids?

Ceramic substrates provide a number of key advantages over standard FR4 based PCBs. One of the primary advantages is their thermal conductivity. For example, Aluminium Oxide (Alumina) offers an increase in thermal conductivity of approximately 20 times that of FR4, and Aluminium Nitride offers an increase of approximately 100 times.

Another advantage of ceramic substrates is that they offer extremely low thermal expansion properties. This makes them ideal for use in harsh environments where extremes of temperature are likely. The combination of low thermal expansion and high thermal conductivity ensures that not only is thermal expansion limited, but it is also evenly spread across the board, limiting the possibility that large amounts of stress will be exerted in specific areas.

Key Benefits:

High reliability for harsh environments

Flexibility to choose precise resistor values with active laser trimming

High voltage resistors

Extended temperature range performance

Improved thermal management

Excellent high-frequency performance

Low start-up costs

Fast lead time to prototype

What Substrates Can Be Used?

At Corintech, we are able to print circuits on the following substrates:

- ADS-96R

- ADS-996R

- ADOS-90R

- All Alumina

- Aluminium Nitride

- Quartz Substrates

- Stainless Steel

Each substrate possesses unique properties, making them suitable for specific purposes. Contact our design team to discuss how you can best utilise thick film technology in your designs.

Contact Us

Call us now on +44 (0)1425 655655. Our experienced team are on hand to discuss your requirements and provide expert advice.

Latest News from Corintech

Corintech is Awarded an EcoVadis Silver Medal

In 2023, Corintech took a bold step to improve our commitment to sustainability. Recognising the necessity of not only advocating for but also implementing sustainable practices. We chose to pursue an internationally approved sustainability rating, an essential factor for smart business today to show and demonstrate our dedication to sustainability.

Corintech Returns to Southern Manufacturing & Electronics 2024

We're delighted to announce Corintech's return to Southern Manufacturing & Electronics 2024, a highlight in the UK's engineering calendar. This prestigious event showcases pioneering technology pivotal to a variety of industries, from machinery and electronics to subcontract services. Set your calendars for the 6th-8th of February at Farnborough International Exhibition Centre. We look forward to seeing you at Stand D165.