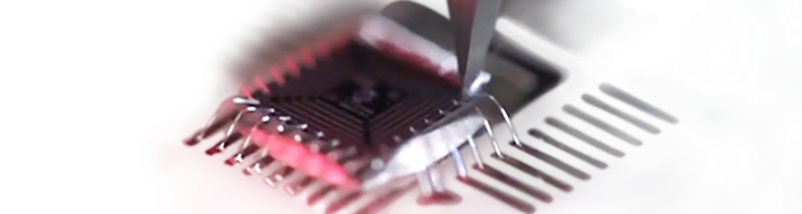

Wire Bonding

Wire bonding is used to electrically interconnect an integrated circuit, or any other semiconductor device, to a compatible metallic surface. A length of small-diameter, soft metal wire is used to make the link, and the bond is created by applying force and ultrasonic vibration. Finished circuits are normally protected with epoxy encapsulation.

Chip-on-board wire bonding is a core part of Corintech’s assembly capabilities, with gold and aluminium wire bonding machines available in the Far East. These give us the capability to work with wire diameters as low as 15 microns for aluminium wire and 25 microns for gold wire.

Ball Bonding

Using our ASM Automatic Wire Ball Bonder, we are able to provide ball bonding solutions for a variety of substrates. Ball bonding techniques allow for the production of more complex wire loops, potentially improving your design efficiency. This machinery’s advanced features and intelligent interface facilitates precision fine pitch bonding with rapid turnaround.

- Higher numbers of inputs and outputs

- Reduced costs from smaller size (less materials required)

- Smaller and lighter final product

- Increased wafer output

- Potentially improved electrical performance

Contact our team today if you want to discuss potential wire bonding enhancements for your product design, or you want your electronics manufacturing carried out to a higher level of quality.

Contact Us

Call us now on +44 (0)1425 655655. Our experienced team are on hand to discuss your requirements and provide expert advice.

Latest News from Corintech

Corintech is Awarded an EcoVadis Silver Medal

In 2023, Corintech took a bold step to improve our commitment to sustainability. Recognising the necessity of not only advocating for but also implementing sustainable practices. We chose to pursue an internationally approved sustainability rating, an essential factor for smart business today to show and demonstrate our dedication to sustainability.

Corintech Returns to Southern Manufacturing & Electronics 2024

We're delighted to announce Corintech's return to Southern Manufacturing & Electronics 2024, a highlight in the UK's engineering calendar. This prestigious event showcases pioneering technology pivotal to a variety of industries, from machinery and electronics to subcontract services. Set your calendars for the 6th-8th of February at Farnborough International Exhibition Centre. We look forward to seeing you at Stand D165.